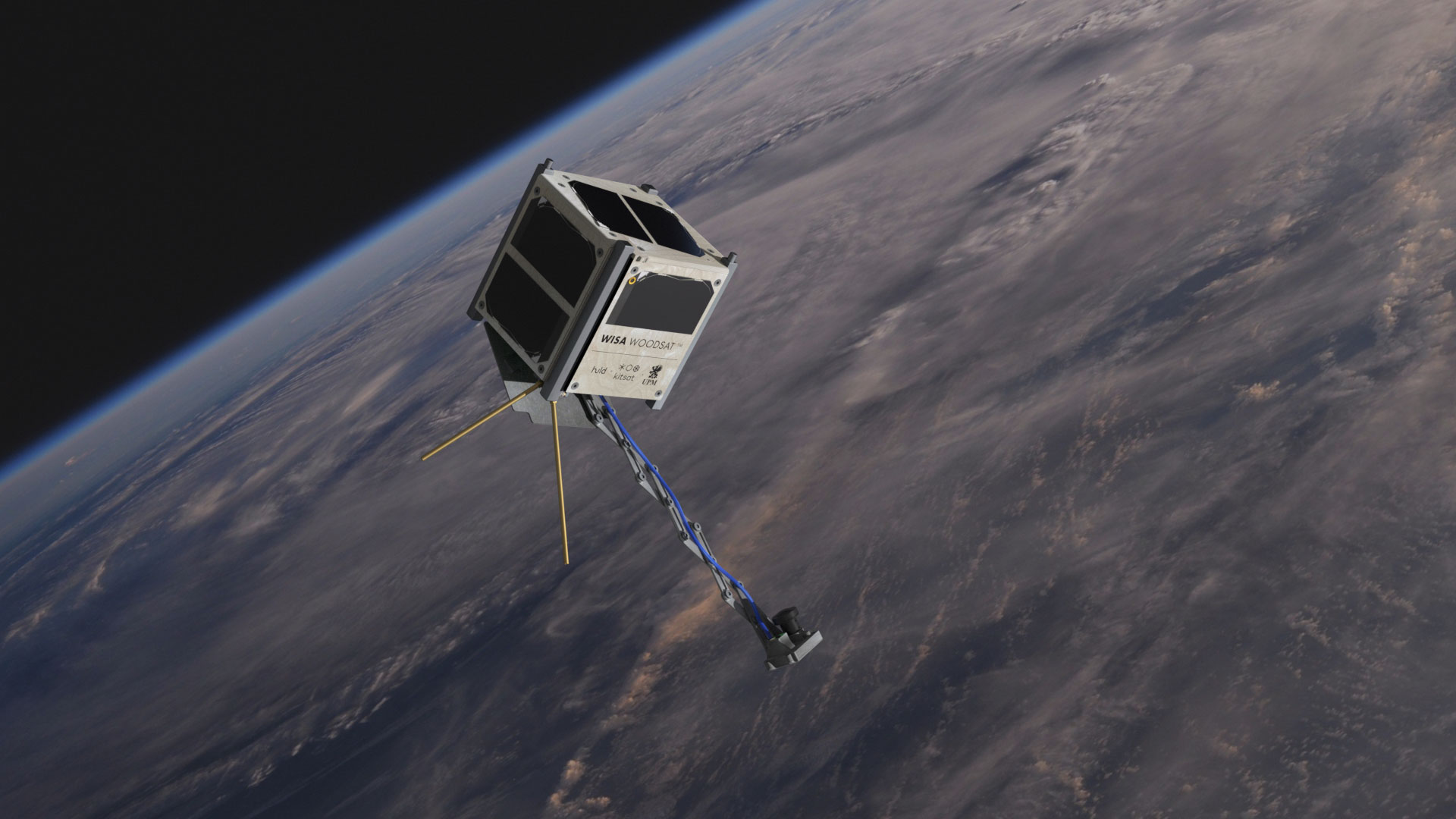

Space, the final frontier. In its quest to conquer it, mankind has employed a variety of exotic materials to build fantastic new devices that can withstand its extreme stresses and temperature. However, its newest innovation promises to be the most unconventional yet. With the launch of the WISA Woodsat in 2022, the world’s first wooden satellite is set to break records.

Supported by the European Space Agency (ESA), the venture is an attempt to see how well plywood can withstand the rigours of spaceflight. And true to form, the minimalistic 10x10x10 cm nanosatellite has been designed and built in Finland – a country known for utilising wood-based materials in new and exciting ways.

The man behind the project is Jari Mäkinen, one of the three founders of Arctic Astronautics, a company known for its innovative methods of popularising space and science. Their award-winning creation Kitsat, a fully functional satellite that can be self-assembled, is already used by science centres, schools, research laboratories, companies and hobbyists around the world.

While Mäkinen had thought about using plywood in a satellite for a long time, recent Japanese research into the feasibility of wooden satellites convinced him that his idea was sound.

“At first it was just a fun idea, but it soon became clear that it was doable. We already had the Kitsat, a real satellite made with inexpensive parts, and it was an easy task to upgrade it to a space-worthy satellite bus. We had already been testing plywood and knew that we could quickly create a structure perfect for a material-science mission,” he explains.

Old doesn’t mean old-fashioned

Plywood is a natural composite material, and it has been used in the aviation industry for a long time. But little research had been done on how it would behave in space. This is why Mäkinen and his team turned to UPM Plywood, which has a lot of experience working with the material.

“We know a lot about wood, and we have the resources to turn wood into different types of commercial products,” says Ari Voutilainen, Director, Stakeholder Relations at UPM Plywood. “We have manufactured plywood for more than a hundred years but that doesn’t mean that it’s old-fashioned. On the contrary, with the right research and development, we can push the boundaries of what the material is used for. In that sense, being able to build a wooden satellite is an exciting technological experiment. The data from the mission will be used for further product development.”

The material chosen for the project is WISA-Birch plywood, and UPM’s product development teams worked hard to test different methods of gluing, surface treatments and super drying to make it as robust as possible.

Fire might come to mind as a possible hazard of using wood, but as there is no oxygen in space, except some sporadic atoms, this is not an issue. In fact, quite the opposite – when the satellite suffers orbital decay and hits the Earth’s atmosphere it burns quickly and cleanly, leaving no space debris behind.

The main problem in extreme space conditions is outgassing, which can result in moisture and gases potentially obstructing optics or harming the electronics. To stop this from happening, the team is testing out two types of protection. The first method is a traditional industrial lacquer that is applied to the satellite’s wooden surface. The second is a futuristic method called ALD, or Atomic Layer Deposition, used normally for electronics and metals. The latter has created a buzz, as the method has potential uses beyond spacecraft.

The WISA Woodsat satellite has raised hopes that space exploration could become more sustainable.

Watching an experiment unfold

To document and reveal any changes in the colouring, or cracks that might occur in the surface, the satellite is equipped with a selfie stick made of 3D-printed metal. The camera has a flashlight for night photography, and the satellite sports a colour calibration card to ensure proper balancing of the colours. The insides of the satellite will be monitored through an instrument suite provided by the ESA, while other sensors measure the effects of atomic oxygen.

The results from the experiment will be invaluable to the ESA and the global space community, as plywood could potentially replace the use of some carbon fibre and other more toxic materials in the future, making space technology more sustainable.

A test model of the satellite completed a successful stratospheric flight in June 2021, and the assembly of the actual satellite is ongoing. The plan is to launch in 2022 from New Zealand. So far, practically everything has been a success, which makes Mäkinen both excited and worried.

“Normally, the process of creating a satellite takes a couple of years or at least 18 months, but we only started six months ago. We have a lot of experience creating devices like this, but that does not stop me from thinking of all the things that could go wrong,” he admits. “Anyway, the plywood parts of the satellite are not my main concern – they have behaved extremely well throughout the process!”

When launched, the WISA Woodsat will be deployed by rocket to an orbit 550 kilometres above our planet. Travelling at a speed of 28,000 kilometres per hour, it will take about 90 minutes for it to travel around the Earth. While the satellite can theoretically stay in the orbit for a decade, Mäkinen says he is prepared for a lifetime of about two years, which is enough to complete the experiment as most of the outgassing will occur during that time.

Everybody’s mission

Mäkinen expects to get a signal from the satellite soon after launch. “If all is well and operating, the camera boom has opened as planned, and the antennas are out, we should be able to get the first test photos and measurements in no time.

“Throughout the mission, the photos and data will be shared on our website and social media. Occasionally, special campaigns will be organised, during which partner ground stations can also beam down photos locally,” Mäkinen says.

In addition, the satellite has a treat in store for all geocachers: if you know what you are looking for, you can find the secret logging code for the TB9GB8G Travel Bug. Mäkinen says that this will be the third-ever space-faring Travel Bug. The first is at the International Space Station and another is hidden in the Perseverance rover on Mars.

When the project is over, the plan is to analyse the whole life cycle of the plywood satellite and compare its performance with more traditional materials. That, in turn, will determine plywood’s role in taking humanity to space.

“Sometimes it’s just easier to use metal or carbon fibre but if plywood turns out to be as good, then why not use that? We will see. That’s what this experiment is for,” says Mäkinen contemplatively.

Main image: Not content with being a global company, UPM is now reaching for the stars.

Illustration: Arctic Astronautics